The Team

Four design engineers make up the core of our consulting team. We have also developed an extensive network of experts to help us meet any design, fabrication, or†testing challenge. Depending on the demands of the specific project, we can team with specialists in tilt-pad journal and foil bearings, the design and fabrication of components using high-temperature alloys, or 5-axis NC machining and prototyping.

From relatively straight-forward turbomachinery component design and analysis, through the full-up cycle analysis, design, and fabrication of a multistage compressor, gas turbine, or a ducted wind turbine and its 90-foot tower, Turbo Solutions has the knowledge and network to complete projects of any size and complexity.

Chip Hobson, P.E.

Partner, Mechanical Engineer

chobson@turbosoleng.comChip is responsible for Turbo Solutionsí project management, general engineering, contracting, and administrative operations. He has more than 25 years of experience in turbomachinery rerates, project engineering and management, equipment and system design, software development, permitting, construction, procurement, startup, and operations. His expertise includes advanced turbomachinery design and development, heat and power cycles, construction management, ASME codes, fuels, burners, boilers, flue gas treatment systems, heat exchangers, cooling towers, tanks and pressure vessels, piping systems, welding, lead and asbestos abatement, coatings, and corrosion control. Chip has worked in the power, process, energy, metals, mining, and agricultural industries. Prior to the creation of Turbo Solutions, he worked for Concepts NREC, Thermoflow, Fluor Daniel, Central Maine Power Company, AMAX Mining, and Farris Brothers Custom Harvesting. Chip obtained his B.S. in mechanical engineering technology from the University of Maine in Orono, and is a licensed Professional Engineer and member of ASME.

Nicholas C. DíOrsi

Partner, Chief Engineer

ndorsi@turbosoleng.comNick leads Turbo Solutionsí aerodynamic and hydrodynamic design and analysis as applied to gas turbines, turbocharged gasoline and diesel engines, vapor compressor refrigeration systems, wind and water turbines, Rankine cycles, and process compression. With more than 25 years of hands-on experience in the design and development of turbomachinery components and systems, Nick has created thousands of unique flowpath designs. His experience includes meanline design, three-dimensional flowpath design, computational fluid dynamics (CFD) analysis, and cycle analysis. Formerly at Concepts NREC, he led the aerodynamic and hydrodynamic design team and was responsible for its compressor, pump, and turbine designs. Prior to that he was responsible for the aerodynamic design of gas turbine compressors and turbines, heat transfer analysis and cooling system design for advanced hot section components, and gas turbine cycle analysis in the Preliminary Design Group at Textron Lycoming. He earned his bachelorís and masterís degrees in aeronautical engineering from Rensselaer Polytechnic Institute in Troy, NY, while working as its Aeronautics Laboratory Instructor.

Garret Harvey

Design Engineer II

gharvey@turbosoleng.comGarret is responsible for the aerodynamic design and analysis of axial and radial compressors, fans/blowers, and turbines, as well as the hydrodynamic design and analysis of axial and radial pumps. Since joining Turbo Solutions in 2010, he has excelled in meanline, three-dimensional inviscid, and three-dimensional viscous flow analysis (CFD) of individual stages and complete turbomachinery systems. Garret is also responsible for Turbo Solutionsí cycle design and analysis work, including Brayton, Otto, Diesel, Rankine, and vapor-compressor refrigeration cycles. In addition, he is skilled in solid modeling of turbomachinery parts and overall assemblies. He holds a bachelorís degree in aerospace engineering from Embry-Riddle Aeronautical University in Daytona Beach, FL.

Andrew Paino

Design Engineer

apaino@turbosoleng.comAndrew is responsible for the mechanical design, solid modeling, and detailed manufacturing drawings of turbomachinery components and overall assemblies. He is also Turbo Solutionsí primary structural designer and analyst, completing detailed stress, deflection, and frequency analysis of components and assemblies. In addition, Andrew performs heat transfer analysis of compressors, turbines, and overall engine and turbocharger assemblies. He is also a skilled CFD analyst of the primary and secondary flowpaths in turbomachinery. He joined the company in 2013 after earning a bachelorís degree in aerospace engineering from Embry-Riddle Aeronautical University in Daytona Beach, FL.

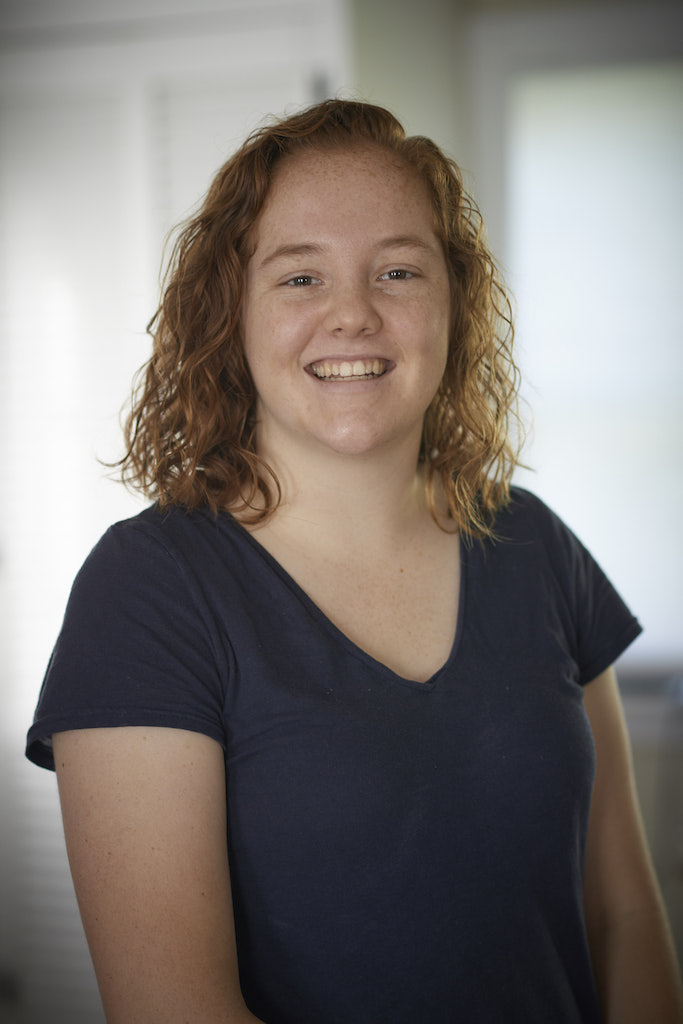

Mary Beth Sareault

Design Engineer

msareault@turbosoleng.comMary Beth is responsible for aerodynamic design and analysis, solid modeling and structural analysis, and test rig design and performance testing of all types of turbomachinery. Mary Beth is skilled both in analytical tasks, such as CFD meshing and analysis, as well as hands-on tasks, such as test rig construction and turbomachinery performance testing. She has worked on a wide range of turbomachinery programs, from rocket turbopumps and gas turbines, to turbochargers and industrial compressors. She holds a bachelor's degree in mechanical engineering from the University of New Hampshire (UNH) in Durham, NH. While at UNH, her senior project was the design, fabrication, and test of a sonar device for mapping of the ocean floor.

Susan Goodwin

Office Manager

sgoodwin@turbosoleng.comSince joining the company in 2005, Susan has been responsible for all accounting at Turbo Solutions, including DCAA-compliant accounting for government contracts. She provides our clients with regular updates on the financial aspects of our programs, and completes all invoicing and tracking of milestones and payments for Turbo Solutions. Susan coordinates purchase orders and payments for our sub-contractors, including engineering services and hardware purchases. She also works with clients to establish and maintain our presence on their accounting systems to streamline internal and external reporting. She holds a bachelorís degree in physical education from the University of Rhode Island in Kingston.